Intralogistic solutions for the food industry

In close cooperation with our business partners we develop customized and efficient logistic technology for your company; trouble free material transfer systems and systematic warehousing. Our machines and conveyors are currently being successfully used in the handling and processing of meat and sausage handling, bakery products, fruit and vegetables, and fish and cheese, to name just a few.

For transporting empty and full crates, cardboard packaging, bulk articles etc there are several different conveyors available. To negotiate different gradients we utilize various kinds of elevator conveyors (e.g. belt conveyors, modular belt conveyors or V-Belt conveyors), depending on the type of goods needed to be transported.

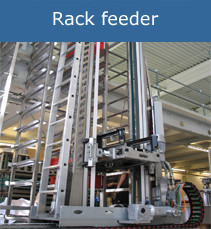

The rack feeder is constructed from stainless materials. It has a slim construction combined with solid engineering for rapidness, long-life cycle and energy efficiency. We use low noise horizontal dragchain systems and stainless steel / aluminium or carbon fiber for the mast construction, depending on the height of the rack feeder. Open construction provides easy maintenance and cleaning.

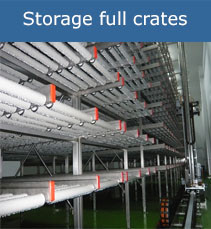

We can deliver storage for empty crates or baskets in various sizes to buffer clean or dirty crates following the first in first out concept. For stacking and unstacking we produce high-performance stacking machines doing more than 1300 baskets/hour. A transport unit carries the stacks to the different parallel belt storage conveyors.

For applications up to six levels we apply a cost-effective loading robot. If it is necessary to reach higher levels (e.g. flow storage buffer store) or to remove crates (e.g. single crate store) we apply our “large” robot. When our engineers constructed these robots they set a high value on energy efficiency and in the event of a breakdown, every part can be changed within an hour.

Ihr Spezialist für Automatisierungstechnik

und Systemintegration Tel. +49 (0) 8041 79268-0

Ihr Spezialist für Automatisierungstechnik

und Systemintegration Tel. +49 (0) 8041 79268-0